Recovery Italia® può aiutarVi a risolvere con successo qualsiasi caso di perdita di dati.

preventivo immediatoComandi ed interfaccia diagnostica per dischi seagate barracuda

Seagate Diagnostic Commands

Upon power up, the drive will respond to a set of diagnostic command send through serial port. Because of the number of commands supported, the commands are broken up into ‘Levels’. Many, the progress may be sent over the serial port for number of bits written and read, and command such as read, write, seek, and error log manipulation are available at several different levels. Diagnostic commands are used in place of ATI scripts to do testing. While the drive is running these diagnostic commandshard/soft error rates, a number indicating the test currently being performed, and various information for status of the current test.

The firmware consists of 2 flash codes and numerous supporting files. The two flash codes are known as factory code and customer code. The factory code contains all the serial port diagnostics command but no AT interface command. The customer code contains all AT interface command but minimal set of serial port diagnostics command.

In the ‘Availability’ column, a ‘F’, ‘C’ and ‘B’ indicate the command is available at ‘Factory Code’, ‘Customer Code’ and ‘Both codes’ respectively.

The following is a short list of some of the serial port commands:

Level T - Certification Tests.

Download code

Start manufacturing test

Set drive ‘Age’

Commands to read cert logs, read error logs, write test data to flash, etc.

Level 1 - Memory Control Commands.

Commands to display buffer, display memory, set memory, copy buffer to flash, read sysvars from disk, etc.

Level 2 - Drive Level Commands

A command to configure the cylinders, heads for testing, gives option for random cylinder/head and random data patterns

Commands to set data patterns, perform ECC tests, manipulate the error log, dump the sequencer ram.

Commands to do physical to logical conversion, assign skips and alternates, etc.

Commands to spinup, spindown, seek, read, write, read long, write long, read compare, sleep, set retries, etc.

Level 3 - Seeking Commands

Display the zone table

Motor acceleration test

Measure head switch & settling times

Display head offset

Move actuator open loop

Seek, seek physical, varying length seek test

Latch test

Display position of actuator

Hysteresis test

Latch Exerciser test

Level 4 - Servo Tracking Commands

Manipulate a skipped cylinder table

Tracking error test

Display position error signal

Zap servo burst

Set servo offset

Set/display tracking gain

Send impulse to actuator

Уровень 5. Используется только в заводских условиях

Уровень 6 – Команды batch файлов

Batch файлы для тестирования запусков-остановок, переключения головок, CSS, тестов 1, 2, 3 коррекции burts, files to test start-stop, head switch, CSS, 1,2,or 3 burst correction test, назначаемые тесты, тесты сравнения данных, возможность вводить различные batch файлы в RAM.

Level 7 - Adaptive Control Commands

Tune parameter control and display

Diagnostic read track

AGC gain control

Perform VCO calibration for all zones

Level 8 - Special Packwriter Commands

- Servo diagnostic sub commands

- Configuration commands

- Lock spin external, spin speed adjust

- Set actuator bias current

Level 9 – Drive Level Command (Full-slipping Defect Management Mode)

Beside the above nine levels of commands, there are two additional sets of commands, the On-line commands and Common commands. The main purpose of On-line command is to display varies type of status. Common command is use to ‘poke’ and ‘peek’ into memoery to allow access to registers, buffer memory and data memory.

2.1 ON-LINE COMMANDS

The On-Line commands may be initiated at any time. For the Interface-specific commands, the Interface code must be present in the current memory map for successful execution; the General commands are always available.

Interface-Specific Commands

|

Command |

Description |

Availability |

|

^E |

Interface State: Max C.H.S. / RW multiple block size / Current transfer mode settings |

B |

|

^F |

Read Segment Record(s) |

B |

|

^G |

Write Queue Dump |

B |

|

^I |

Controller Register Dump ** (See figure 2.1.7) |

B |

|

^K |

Reserved |

|

|

^Q |

Reserved |

|

|

^R |

Reserved. This command can only be used when the drive is spun down |

|

|

^S |

Snapshot current execution address |

B |

|

^V |

Interface Command Echo and Activity Trace Toggle |

B |

|

^X |

Interface and Niwot Command History ** (See figure 2.1.6) |

B |

|

^Y |

Display Raw SMART Values (used for computing SMART Attributes) |

B |

|

‘~’ |

Interface Command State |

B |

|

|

|

|

General Commands

|

Command |

Description |

Availability |

|

^B |

(Reserved for Servo Use) |

F |

|

^D / ^N |

Retry Activity Display Toggle.

A message will be displayed as follows: e c r = 0 1 0

where ‘e’ = error tracing, ‘c’ = command tracing & ‘r’ = retry tracing. 0=disable, 1=enable.

When enabled causes the following characters to be sent to the serial port: ‘.’ = First data retry ‘,’ = subsquent data retry ‘c’ = Successful On-The-Fly correction occurred ‘f’ = Shifted Header retry. ‘H’ = Header retry ‘I’ = Sequencer was force-stopped. ‘s’ = Servo Recovery ‘w’ = Write Retry ‘+’ = Index active on non-index sector ‘D’ = Spin speed outside of tolerance ‘L’ = Latch retry ‘X’ = Resync servo bursts ‘<’ = Fine Track window exceeded. ‘$’ = Missing servo burst mark. |

B |

|

^L |

Display Sign-on Message, including firmware version. |

B |

|

^O |

Advanced Servo Tracing |

B |

|

^P |

Power Chop enable/disable toggle. |

B |

|

^T |

Restart Test. Causes the drive to restart testing at the current age. |

B |

|

^C |

Software Reset Command, Causes the drive to spin down re-initialize itself, spin backup, and come ready again. |

B |

|

^Z |

Restart the Diagnostic Monitor. |

B |

|

! |

Display Current R/W Channel Settings |

B |

|

% |

Show Mux Status. ** (See figure 2.1.1) |

B |

|

‘ |

Display Transfer Status (See figure 2.1.2) |

B |

|

. |

Display Active Status. ** (See figure 2.1.3) |

B |

|

; |

Display Machine Status. ** (See figure 2.1.4) |

B |

|

< |

Decrement read/write scope synchronization pulse position. |

B |

|

> |

Increment read/write scope synchronization pulse position. |

B |

|

? |

Show Buffer Allocation. ** (See figure 2.1.5) |

B |

|

^ |

Show Elapsed Time since start of cert test or last ^Z. |

B |

|

` |

Show Read/Write Statistics. |

B |

|

{ |

(Reserved for Servo Diagnostic Use) |

B |

|

} |

(Reserved for Servo Diagnostic Use) |

B |

|

ESC |

Interrupt Loop or Batch file execution. |

B |

|

= |

Display power up time |

B |

Figure 2.1.1: ‘%’ command display format

Returned data format:

aabbccccddeeffgg AX'iiiiiiii ' “jjjjjjjjjjjj’

|

aa |

Age |

|

bb |

Program |

|

cccc |

Accumulated health |

|

dd |

Drive type |

|

ee |

This is the Atlantis ECA0h WRSTATS register value |

|

ff |

Error code byte |

|

gg |

Maximum number of heads for this type |

|

iiiiiiii |

Drive serial number |

|

jjjjjjjjjjjj |

PCBA serial number |

Figure 2.1.2: ‘ ‘ ’ command display format

Returned data format:

Cmd Cyl Hd Sct Cnt Stbuf Segl Csct Cbuf Actv Ercd Rtry Flags

aa bbbb cc dddd eeee ffff gg hhhh iiii j kk mmmm.nn.pp qq

|

Cmd aa |

Last command type |

|

Cyl bbbb |

Cylinder of current command |

|

Hd cc |

Head of current command |

|

Sct dddd |

Start sector of current command |

|

Cnt eeee |

Length or block count |

|

Stbuf ffff |

Start buffer number |

|

Segl gg |

Buffer size

|

|

Csct hhhh |

Current Sector |

|

Cbuf iiii |

‘Intfwork1’ address |

|

Actv j |

CIP |

|

Ercd kk |

Error Code |

|

Rtry mmmm.nn.pp |

Retry parameters (see level 2 Y command) mmmm - retry control bit nn – read retries count pp - write retries count |

|

Flags qq |

R/W flags |

Figure 2.1.3: ‘ . ’ command display format

Returned data format:

Pgm=aa Trk=bbbb(cccc).d.eee Zn=f Err=gg ErCt=hhhh Hlth=iiii Chlth=jjjj Ready

|

Pgm=aa |

Active program 00 is diagnostic monitor. 50 is interface program All other numbers are current test running. |

|

Trk=bbbb(cccc).d.eee |

Currently selected logical cylinder (physical cylinder), head, sector. |

|

Zn=f |

Zone |

|

Err=gg |

Error code from current operation |

|

ErCt=hhhh |

Error count since last reset of drive or last reset error log command |

|

Hlth=iiii |

Accumulated health bits - four digits |

|

CHlth=jjjj |

Current health bits – four digits |

|

Ready |

Drive status. Can be Ready or Ntrdy

|

Figure 2.1.4: ‘ ; ’ command display format

Returned data format:

Age=aa Type=bb MxCyl=cccc MxHd=d MxSct=eee Bsz=ffff TCode=gggg

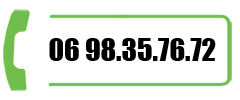

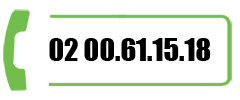

Hai bisogno di aiuto o di maggiori informazioni ?

Contatta il nostro call center o inviaci una richiesta di assistenza a info@recoveryitalia.it. I nostri esperti sono a tua completa disposizione per una consulenza gratuita.